We believe in the power of innovation and excellence. We are a dynamic and forward-thinking company dedicated to providing top-notch spinning solutions to our valued clients.

Expertise

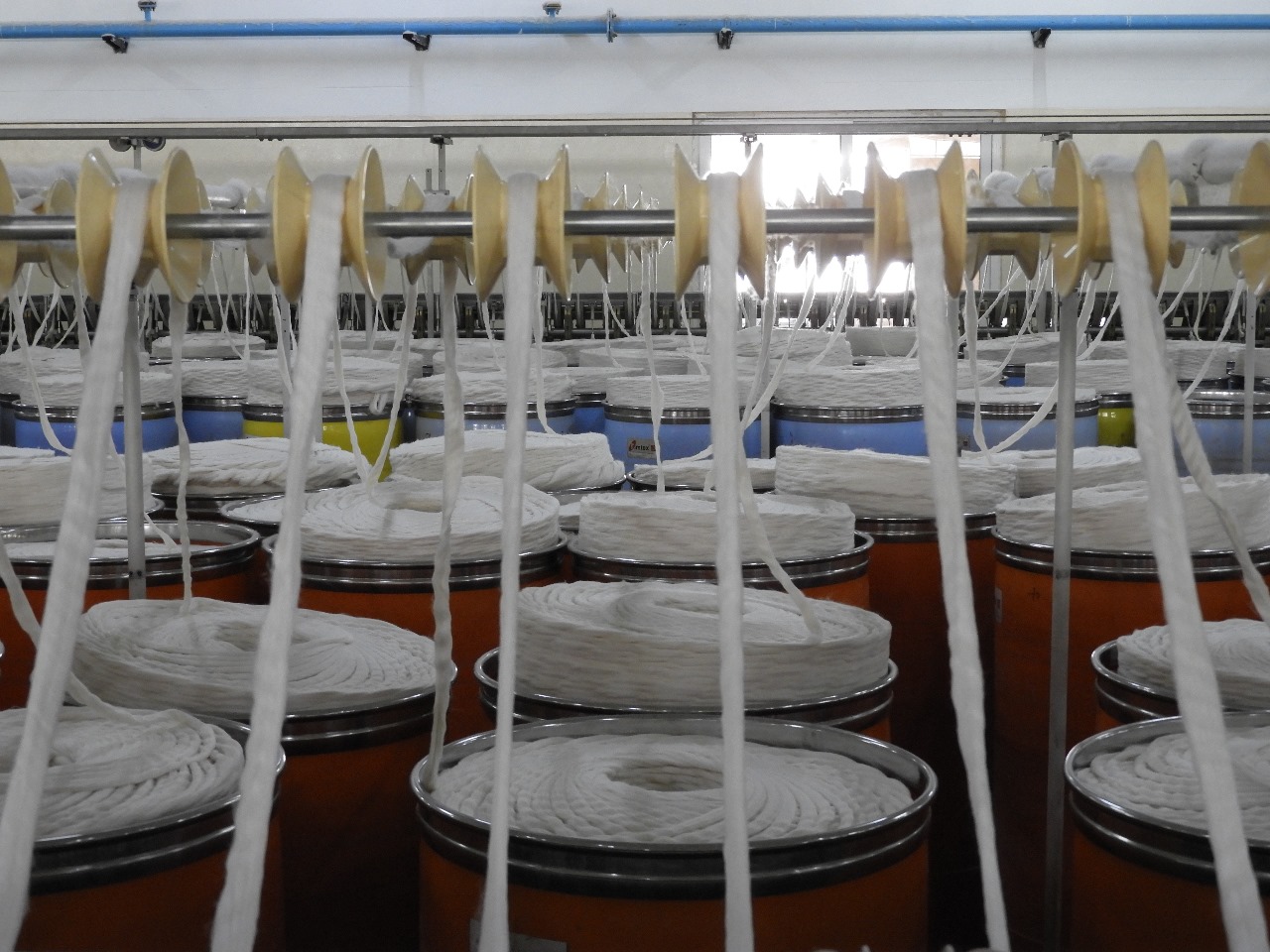

Our team consists of industry experts who possess in-depth knowledge and experience in Spinning Machines. We are at the forefront of industry trends, ensuring that our clients benefit from the latest advancements.

Customization

We understand that every business is unique. That's why we offer tailored solutions that address your specific needs and challenges. Our services are flexible and scalable, accommodating your evolving requirements.

Quality

We never compromise on quality. Our meticulous attention to detail and rigorous quality assurance processes guarantee that you receive the highest standard of workmanship and deliverable.

Timeliness

We value your time and strive to meet deadlines without compromising quality. Our efficient project management ensures that your projects are delivered on schedule.

OUR MISSION

Our mission is to deliver automation systems that not only drive efficiency and productivity but also set new standards for excellence and reliability in textile machinery conversion. We believe that by prioritizing quality , we empower our clients to achieve unparalleled success and sustainability in their operations, setting a benchmark for the industry to follow.

OUR VISION

We envision a future where our manufacturing processes are not only state-of -the-art but also environmentally responsible. We aim to be beacon of excellence, known for setting the highest standards of quality and reliability in the machines we produce.

2016 - From Birth to a Period of Growth

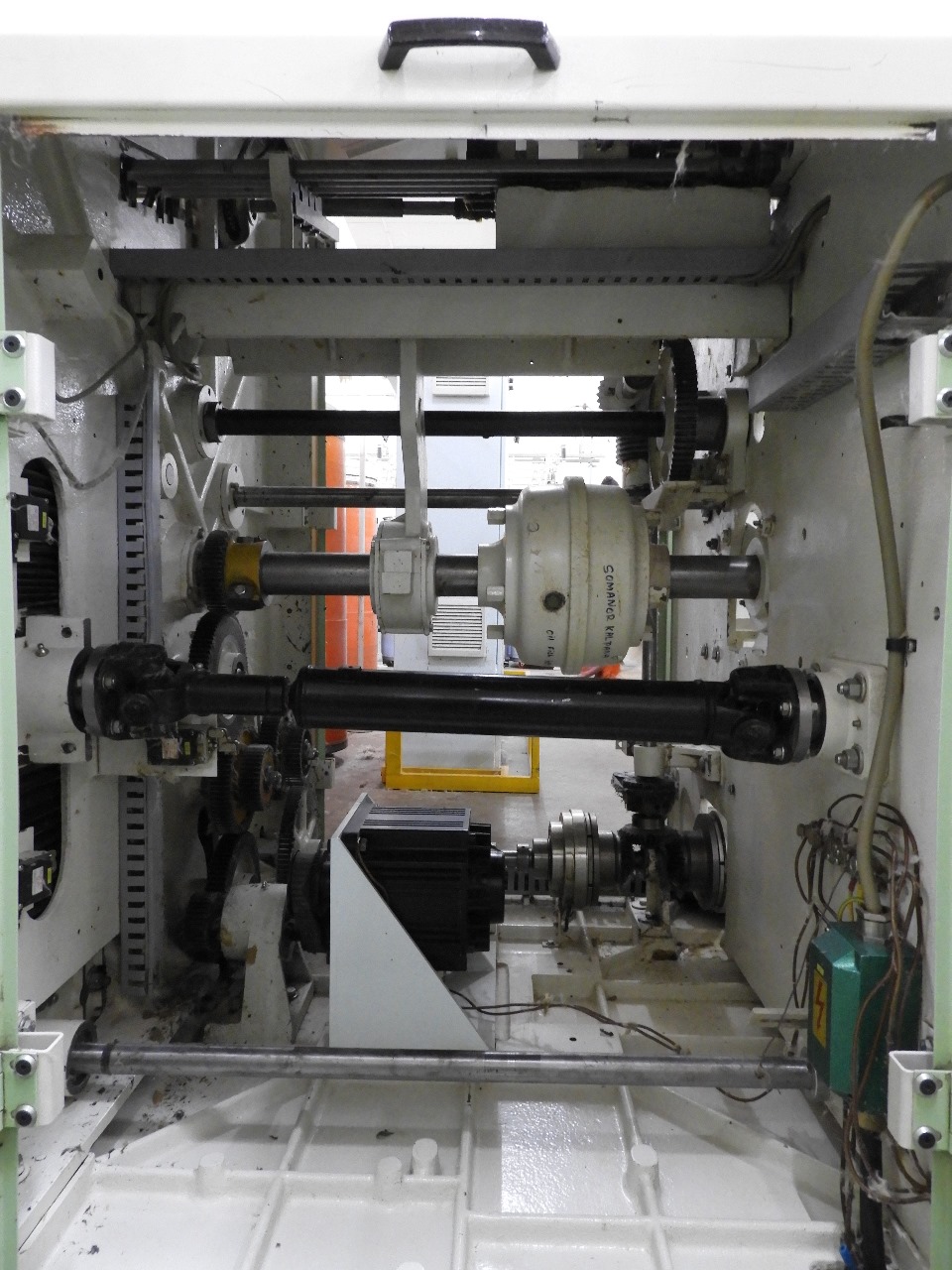

In 2016, we reached a significant milestone by introducing taper formation in the speed frame machine, followed by the successful inverter conversion. In the subsequent phase of our conversion journey, we achieved a major breakthrough by implementing the Roving Automation Conversion System, which involved the elimination of the Builder Motion and the Cone Drum.

2019 - Creation of Demand and New Business

In 2019, we embarked on a transformative journey with the implementation of the Electrical Ring Rail Conversion System for the Ring Frame machine models LR6, LR6/s, and G5/1, primarily aimed at reducing restarting breakages, achieving mechanical reduction, and driving production improvements. This system was also designed to accommodate Inverter machines, including Inverter conversion, as well as machines without inverters.

2023 - Opening up Limitless Worlds of Potential

In 2023, we embarked on an unprecedented journey by implementing the Differential Gear Less Conversion in the speed frame machine. This groundbreaking step not only brings us closer to achieving full automation but also eliminates the need for maintenance associated with the differential gear box. Additionally, we undertook the upgrade of the Zinser 670 to inverters, aligning with our future plans to continuously enhance and innovate our manufacturing machines for increased efficiency and productivity.